Mechanical Engineering Technology (MET) prepares students for mechanical engineering careers in manufacturing, design, quality, and processing. Graduates gain hands-on experience, making them highly sought after by employers in maritime, aerospace, energy, automotive, pulp and paper, defense, and other industries.

UMaine MET students designed an adaptive wheelchair for shooting competitions

The University of Maine’s Mechanical Engineering Technology (MET) program is all about real-world problem solving. When athlete and activist Enock Glidden came to the MET capstone with a unique challenge — to adapt his wheelchair for shooting competitions — students met the task with skill, creativity and an open-mindedness that resulted in a useful finished project, and a lifelong bond.

Mechanical Engineering Technology Overview

Mechanical Engineering Technology (MET) is a broad field which prepares students to work as mechanical engineers designing, developing, and manufacturing new and innovative products and technologies. Mechanical engineers with an MET degree are involved in every process, from designing delicate tools and parts, to working on huge gears in large vehicles, to operations and maintenance.

Throughout the program students are preparing for professional practice by developing both technical and interpersonal skills. Early in the program students learn to create 3D computer models and communicate with 2D drawings. Then they learn to bring drawings to reality in our workshop. They develop skills by working on diverse teams.

Students acquire math and science skills through a structured math sequence and courses in physics and chemistry. They continue to build a solid foundation of engineering knowledge and skills. Topics include heat and work, materials, support and motion of rigid bodies and fluids, manufacturing processes, and electrical circuits. Students also learn to write and speak about technical issues as well as measure all things mechanical.

Students learn how to design complex mechanisms, then apply all their learnings to a senior capstone project. During the capstone project, students find a real-world problem, design a solution, then build and test their design.

Students are urged to work in a technical job during each summer break. If the job meets certain requirements students may obtain 3 hours of co-operative education degree credit via MET 394.

The Mechanical Engineering Technology (MET) program is accredited by the Engineering Technology Accreditation Commission of ABET, https://www.abet.org.

Programs Offered

Undergraduate Degrees

UMaine Course Catalog, Overview of Degree Requirements.

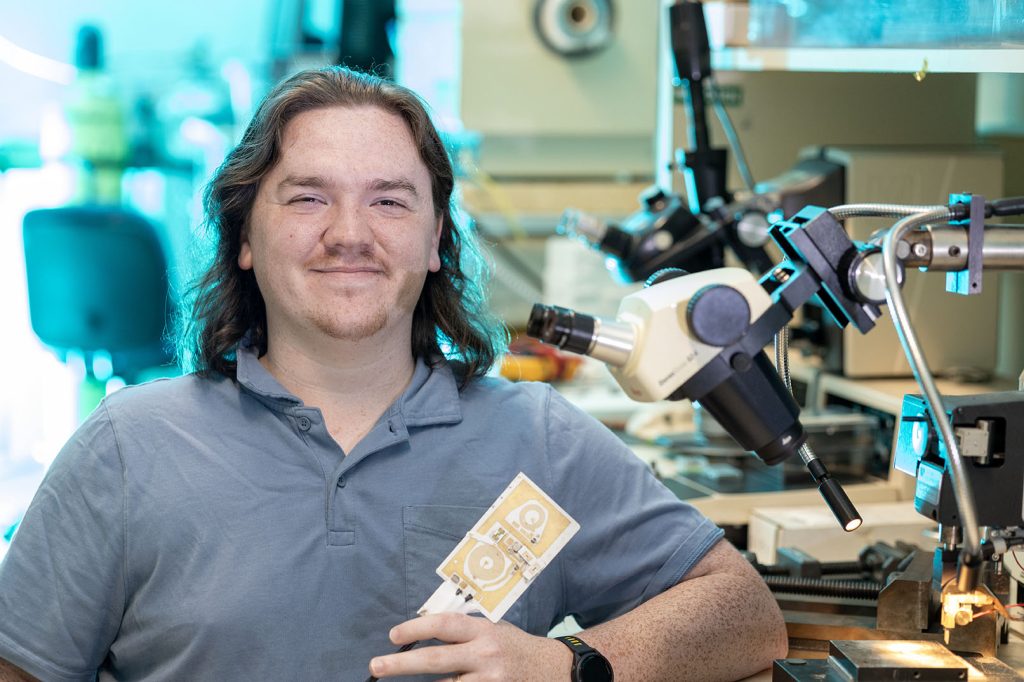

Fabrication Projects

And with us you’ll learn how!

Engineers routinely design for and work with machinists. To do so, you will need to understand machining processes. Don’t know how to machine, no problem. In fact, only a few first-year students have prior machining experience. If you’ve never machined before, think of machining as high-end arts-and-crafts – or very meticulous sculpture.

MET prepares you for your engineering career by giving you hands-on machining experience.

First you’ll learn the computer-aided design (CAD) skills to make an image of what you want to fabricate.

Then you’ll fabricate the parts from your detailed drawings.

All students learn to program the computer numerical controlled (CNC) mills and lathes, including using computer-aided design/computer-aided machining (CAD/CAM) software to translate a part drawing into a machining program.

Some students also choose an elective course to design and fabricate more complex parts

Although most students starting in MET have no experience machining or welding, a few do have prior experience in one or the other of these areas. You won’t become a machinist or a welder in our program, but you will be able to make what you design!

Why choose MET?

MET is an adaptable major. So no matter how much your interests evolve during your college years, your MET degree will still be applicable for reaching your post-grad dreams! Here are examples of what being an MET student is like: MET graduates help us conserve energy at Efficiency Maine, while keeping our feet comfortable making New Balance Shoes. At iRobot Corp they keep our soldiers safe by finding roadside bombs using robots. They design efficient building heating and piping systems at Woodard & Curran. MET graduates support national defense building and repairing naval vessels at Bath Iron Works and Portsmouth Naval Shipyard, supply us with Chinette paper plates produced at Huhtamaki Co., provide electrical power from turbines built at General Electric Power Systems, and keep us on the move manufacturing jet engines at Pratt & Whitney. About 70% of our graduates work in Maine.

Programs Videos

Frequently Asked Questions

Curious about Mechanical Engineering Technology? Whether you’re a prospective student exploring career options or a current student looking for program details, this FAQ covers everything you need to know. From course topics and career opportunities to hands-on learning and industry demand, get answers to your most common questions about this exciting and evolving field.

Our Faculty & Staff

At MCEC, our faculty is the heartbeat of our academic community. Dedicated, inspiring, and deeply knowledgeable, our professors go beyond the traditional classroom experience to foster real-world skills and a passion for learning. Whether mentoring, leading innovative research, or providing personalized support, our faculty members are committed to empowering students to achieve their highest potential

Engineering and Engineering Technology – Similarities and Differences

Many engineering graduates find roles as “engineers”, but the differences between various engineering degree programs and the nature of the jobs they lead to are often unclear. A look at the history of these programs helps to better understand their evolution.

School of Engineering Technology Contact Information

Erin Ellis

um.set@maine.edu

Administrative Specialist

Erin Wight

um.set@maine.edu

Academic Coordinator

Kayla Bouchard

um.set@maine.edu

Administrative Supervisor

5711 Boardman Hall,

Room 119

Orono, Maine 04469-5711

Tel: (207) 581-2340

MCEC NEWS